Welding, Bonding & Electronics Packaging Equipment

|

ULTRASONIC METAL WELDING SYSTEMS • SPOT WELDERS • WIRE SPICERS • BARTTERY PACK WELDERS • POWER SUPPLIES |

Sonics' 15, 20 and 40 kHz ultrasonic spot welding systems deliver unique advantages due to the patented nodal mounting system. The quickest tool changes in the industry and unsurpassed reliability have made this product line an industry favorite. Sonics offers a wide range of configurations, each optimized for R&D, manual operation, specialized machines, or full automation. Standard versions are available for foil welding and wire processing. Sonics’ power supplies come in 2 versions, the SmartControl (MSC) Series with full color touch screen controls and the MX Series, with standard keypad operation. Power levels range from 400 to 6000 watts for actuators in the 40, 20 and 15 kHz frequencies. |

-

-

• CO2 CLEANING

• CHEMICAL FREE

• RESIDUE FREE

• MANUAL TO IN-LINE

acp systems AG is a global technology leader in advanced clean production, affiliated process automation and system integration headquartered in the south of Germany. Our core technologies are quattroClean snow jet cleaning, micro-dispensing and smart handling. Since 1997 we support our customers in the development, planning and integration of highly automated cleaning processes, for example within the electronics, medical and automotive industry.

-

-

-

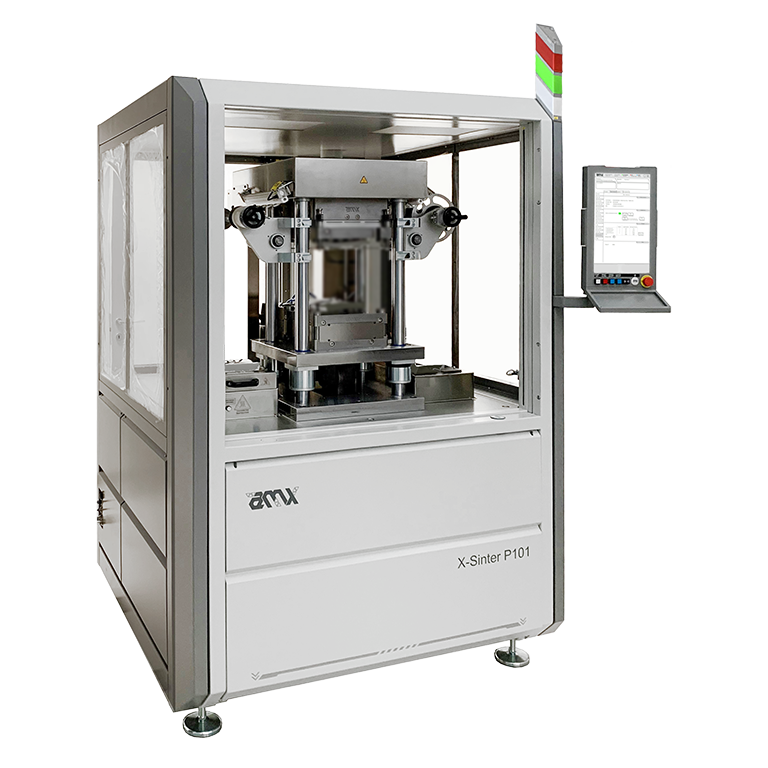

• SILVER SINTERING

• COPPER SINTERING

• MANUAL TO IN-LINE

Pressure sintering (silver sintering or in the next future copper sintering too) is a die attach heat treatment process applied to a powdered material in order to give it higher strength, integrity and conductivity. Pressure sintering is now considered the most reliable technology for power electronics packaging.

Our experienced R&D team can support you choosing the best solution for your specific silver sintering and copper sintering applications, choosing from a wide variety of sintering presses. AMX sintering press range covers all the customers’ needs: R&D, small batches, low volume and high volume of productions.

-

-

-

• LASER RESISTOR TRIMMING

• LASER CUTTING

• LASER DRILLING

• CAVITIES & VIAS

PPI Systems designs and manufactures the most advanced turnkey laser resistor trimming solutions for modern hybrid circuits and electronic components. Whether small-lot, high-mix production needing a flying probe solution, high-volume low-mix production needing a probe card solution, or a unique problem needing a custom probing solution, PPI has the products and experience to help. From standard component and circuit trim to complex active-trim scenarios with custom fixturing, the RapiTrim products are The Future of Resistor Trimming™.

-

|

• VACUUM PRESSURE FURNACES • FLUXLESS VOID-FREE SOLDERING |

Centrotherm is a world Leading Supplier for vacuum and pressure furnaces for vacuum soldering, brazing and sealing for microelectronics packages and components. The VLO system platform covers a wide range of applications fromm R&D processing to high-volume production.

Centrotherm Technologies and Solutions

|

|

|

Lasers and Systems • LASER MIRCO-MACHINING • LASER MARKING • LASER CUTTING • LASER WELDING |

Amada Weld Tech offers a complete range of turn-key semi-automated laser marking, laser engraving, laser welding, laser cutting and laser drilling machines and systems, providing the fastest path from application concept to full production. Amada Weld Tech not only manufactures the laser hardware, but also engineers and integrates laser systems, offering designers a one-stop shop for system integration. This includes running samples of the process in-house to ensure it does the entire job as specified, and answering in-depth application questions. Laser Marking Systems |

|

-

Resistance Welding Systems

• RESISTANCE WELDING

• HOT BAR REFLOW SOLDERING

• ACF BONDING AND HEAT STAKING

While Amada Weld Tech America did not invent resistance welding, it perfected the technology and was the first to apply it to welding small microelectronic modules in the early 1950¹s. Today, Amada Miyachi offers a wide range of welding technologies which have been used successfully for decades. Core resistance welding technologies include Linear DC, High Frequency Inverter, Capacitiv Discharge and AC. They are used for resistance spot welding, seam welding, gap welding, projection welding, thermo compression bonding, strand welding and insulated wire welding.

|

Benchmark Hermetic Sealing Systems & Gloveboxes • PARALLEL GAP HERMETIC SEALING

• LASER SEAM WELDING • PROJECTION WELDING |

Amada Weld Tech offers a complete line of resistance welding based systems including projection welders, rotary welders, hermetic seam sealing systems, and lid placement and tacking systems. The company also provides atmospheric enclosures (gloveboxes and dryboxes) for hermetic sealing applications. Because Amada Miyachi designs and manufactures both the power supply and the hermetic sealing system, you are assured that the motion, power supply, software, and tooling will work properly and are integrated into a whole that supports your desired process flow. Hermetic Sealing Systems |

|

|

• FULLY AUTOMATIC AND MANUAL WIRE BONDERS • GOLD BALL BONDING • THIN AND THICK WIRE • HEAVY RIBBON BONDING |

F&S Bondtec Austria serves the desktop equipment segment and supplies the most complete program worldwide for bonding and testing equipment. Only F&S Bondtec Austria can offer you a secure investment into the future: our Desktop-Micro-Factory which provides all wire bond processes and, in addition, all test methods in a single desktop machine base.

|

|

-

-

• FULY AUTOMATED DIE BONDERS

• FLIP CHIP BONDING

• THERMOSONIC BONDING

• ULTRASONIC BONDING

• DISPENSING

The T-6000-L/G is an enhanced version of the proven T-6000-L series. A fully automated all-purpose system built on a sophisticated granite gantry and high precision motion control system. T-6000-L/G can be upgraded with new loader and unloader modules. The throughput for the latest advanced packaging applications has been extremely improved. With numerous available options, the T-6000-L/G can be customized to suit all market needs. This system offers our customers the opportunity to grow from a manual manufacturing process to a fully automated process without any additional hardware changes. Just a few software clicks will guide you through this process.

-

|

• MULTI-ZONE BENCHTOP REFLOW OVENS

|

Sikama’s innovative line of SMT Reflow Soldering Ovens include both straight conduction systems and Sikama’s patented Conduction + Convection Ovens. Many of our systems are available with liquid cooling and optional software control for both data logging and remote operation, as well as an optional speed/time dwell mode. Our Sweeper Bar technology allows you to integrate our systems into automated production lines with our optional loading and off-loading accessories. The atmospheric control features found on many of our systems ensure quality bonding in an inert gas environment.

|

|

|

• BATCH PLASMA TREATMENT SYSTEMS • REACTIVE ION ETCHING SYSTEMS |

Nordson MARCH is the global leader in plasma cleaning and plasma surface treatment equipment, and plasma applications technology. The company has designed and manufactured plasma surface treatment equipment for more than 30 years and has broad experience in the areas of advanced semiconductor packaging and assembly, wafer level packaging (WLP), printed circuit board manufacturing, life science & medical device assembly, and various large-scale industrial applications. |

|

|

• DISPENSING AND CONFORMAL COATING SYSTEMS |

Nordson ASYMTEK is a world leader in precision automated fluid dispensing, jetting and conformal coating We design and manufacture a full line of equipment for PCB and SMT assembly, semiconductor packaging, 3D and wafer-level packaging, camera module assembly, case and packaging assembly, LED assembly, and other precision manufacturing. We support our products with a global service network. Fluid Dispensing Systems and Equipment |

|